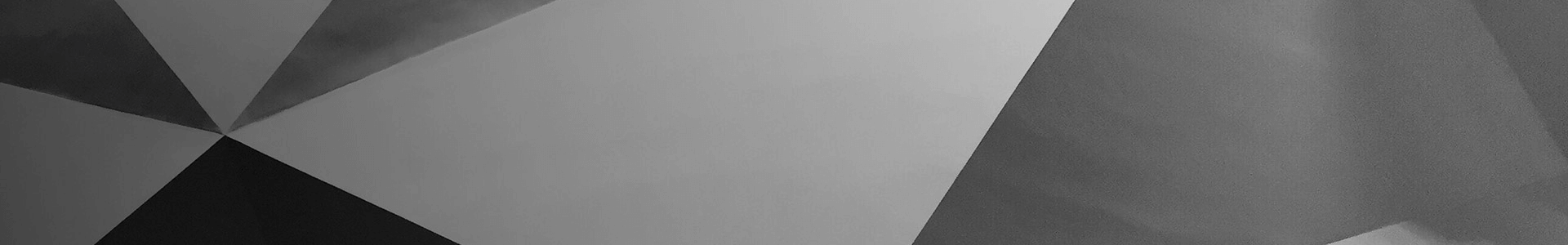

Powerful PE PP ABS PS PC PMMA Pet Waste Plastic Film Bag Hard Lump Shredding Single Double Shaft Shredder Machine

Overview Kwell Powerful PE PP ABS PS PC PMMA PET waste plastic film bag shredding single double shaft shredder Machine P;

Overview

Single shaft shredder is mainly used in all kinds of hollow or solid plastic material.The machine is suitable to PE, PP, PET, ABS, PVC and engineering plastics.It is new designed especially for crushing various big solid material, unmanageable material, plastic container and barrel, plastic film, plastic pipe, fiber and paper which the normal crusher can not handle.The shredder absorbed advanced technolgy combined with long-term repeated practice and development.It efficiently capable for shredding materials that are quite thick and tough such as large plastic pipes,and especially for recycling different materials.the shredder uses close-packed structures with hydraulic feeding system.It's featured as advanced equipment,strong crushing capacity and high output.the machine uses of siemens to ensure the safe operation of system.

Q1. How do you guarantee the quality of your products?A1: KWELL Machinery guarantees all new products and parts to the first owner-operator to be free from defects in material and workmanship for a period of 60 months from B/L date, under normal use and service.Q2. How about the spare parts?A2:We could provide you reliable, fast and professional service through telephone, network and on-site at any time. Normally, we send our customer one set of spare parts together with the machines when we deliver the product.During the warranty, we provide new parts free of charge for you to replace, exclude the parts broken that caused by improper operation.In our spare parts department, you will get professional technical advice, as well as the relevant information regarding all products and services.Q3. About product qualityA3:KWELL is a prestigious plastic recycling and extrusion machinery manufacturer in China. Our customers have been enjoying a variety of advantages in particular in terms of the dedicated screw designed by our R&D team including good mixing, good dispersion, high productivity, and so on.Q4. After-sales serviceA4: 1.Send engineers to install, test the machines and offer technology guidance and worker training at customers' factory. 2.Offer 5 Years free maintenance and life long service. After the warranty period, spare parts will be provided at basic cost. 3.Build customers database. All machines are traceable. 4.Visit customers and make quality trace periodically and take customers' feedback into account during routine practices. 5.Speed up service and spare parts supply.

Basic Info.

| Model NO. | WT400/600/800/1000/1200/1400/1500/1600 |

| Knife Roll | Solid Knife Roller |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, QS, GMP |

| Brand of Inverter | ABB |

| Brand of Motor | Siemens |

| Feeding Way | by Conveyor |

| Screen Sieve Size | 30mm-80mm |

| Color | Optional |

| Touch Screen | with |

| Material of Blade | SKD-11, DC-53 |

| PLC | with |

| Suitbale Material | PE PP PVC ABS PS |

| Transport Package | Seaworthy Packing |

| Specification | 50-3000kg/h for single shaft shredder |

| Trademark | KWELL |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 50 Sets/Month for Shredder |

Product Description

Kwell Powerful PE PP ABS PS PC PMMA PET waste plastic film bag shredding single double shaft shredder MachineProduct Description

Single shaft shredder is mainly used in all kinds of hollow or solid plastic material.The machine is suitable to PE, PP, PET, ABS, PVC and engineering plastics.It is new designed especially for crushing various big solid material, unmanageable material, plastic container and barrel, plastic film, plastic pipe, fiber and paper which the normal crusher can not handle.The shredder absorbed advanced technolgy combined with long-term repeated practice and development.It efficiently capable for shredding materials that are quite thick and tough such as large plastic pipes,and especially for recycling different materials.the shredder uses close-packed structures with hydraulic feeding system.It's featured as advanced equipment,strong crushing capacity and high output.the machine uses of siemens to ensure the safe operation of system.

Product Parameters

| Model | Power(KW) | Qty. of Rotary blades(PCS) | Rotating Diameter(mm) | Shredder Chamber Size(mm) | Capacity(kg/h) |

| WT300 | 5.5 | 20 | Φ150 | 300*300 | 50-100 |

| WT400 | 11 | 22 | Φ220 | 400*500 | 100-200 |

| WT500 | 18.5 | 28 | Φ250 | 500*550 | 200-300 |

| WT600 | 22 | 33 | Φ280 | 600*680 | 300-400 |

| WT800 | 37/45 | 51 | Φ350 | 860*960 | 500-1000 |

| WT1000 | 55 | 63 | Φ350 | 1100*1150 | 800-1500 |

| WT1200 | 75 | 69 | Φ400 | 1200*1400 | 1800-2500 |

| WT1400 | 110 | 95 | Φ550 | 1400*1480 | 2000-3000 |

Detailed Photos

Photos of single shaft plastic shredding machine/waste plastic shredder:

Company Profile

Q1. How do you guarantee the quality of your products?A1: KWELL Machinery guarantees all new products and parts to the first owner-operator to be free from defects in material and workmanship for a period of 60 months from B/L date, under normal use and service.Q2. How about the spare parts?A2:We could provide you reliable, fast and professional service through telephone, network and on-site at any time. Normally, we send our customer one set of spare parts together with the machines when we deliver the product.During the warranty, we provide new parts free of charge for you to replace, exclude the parts broken that caused by improper operation.In our spare parts department, you will get professional technical advice, as well as the relevant information regarding all products and services.Q3. About product qualityA3:KWELL is a prestigious plastic recycling and extrusion machinery manufacturer in China. Our customers have been enjoying a variety of advantages in particular in terms of the dedicated screw designed by our R&D team including good mixing, good dispersion, high productivity, and so on.Q4. After-sales serviceA4: 1.Send engineers to install, test the machines and offer technology guidance and worker training at customers' factory. 2.Offer 5 Years free maintenance and life long service. After the warranty period, spare parts will be provided at basic cost. 3.Build customers database. All machines are traceable. 4.Visit customers and make quality trace periodically and take customers' feedback into account during routine practices. 5.Speed up service and spare parts supply.

You may also like

Send inquiry

Send now